Flight has always captured mankind’s imagination, which is evidenced by the great variety of aerial vehicles that exist today. Everything from fixed-wing to helicopters; sailplanes to spaceships; mono-wing to quadrotor. However, despite the wide variety of flying vehicles, not one of them has attained persistent flight. Accomplishing this feat is the last great aviation milestone.

MOTIVATION

Satellite Demand

Satellites have had a profound impact on our society by connecting the world through telecommunications, delivering precise locations with positional navigation, and enabling imaging and sensor systems to significantly increase our understanding of our planet as well as the entire universe. But there is still a need for even greater capabilities while delivered at a lower cost. Society has developed an increased appetite for omnipresent communications, surveillance capabilities, and instant access to information. More recently, the expectation is for these services to be achievable in real-time as on-demand services. These new capabilities are not well met by existing satellites, and will require a new solution with several orders of magnitude lower signal latency, greater operational flexibility, and dramatically lower costs.

Classes of Satellites

Various types of satellites are currently in practice, each having its own strengths and weaknesses. Geosynchronous satellites offer a continuous coverage capability with a single satellite. Low Earth Orbit (LEO) satellites are fifty times closer for improved single latency, power requirements, and imaging resolution; but require a fleet to be operational. Atmospheric satellites, also known as High Altitude Platform Stations (HAPS), are another fifty times closer for even better latency, power, and resolution; and are reusable with extremely low capital costs.

Geosynchronous Satellites

Fixed point for continuous coverage

Farthest distance, greatest area

Large transmission delay

Significant power loss to transmit

Low Earth Orbit (LEO)

50 times closer than Geo Sat

Constant orbit, no fixed point

Need a fleet for complete coverage

Not capable of two-way transmission

Atmospheric Satellites

Operate ~60k-70k ft

50 times closer than LEO Sat

Broadband transmission speeds

Takeoff and landing reduces costs

Limitations

A persistent flight capability is needed before Atmospheric Satellites become a reality. However, current fixed-wing aircraft designs have pushed the boundaries of structural material capabilities, and cannot accomplish the task with readily available solar cells and battery technologies. Even with cutting-edge exotic composite materials, conventional designs are unable to incorporate enough strength and stiffness to employ the long and slender wings needed to achieve better aerodynamic efficiency. Consider the NASA/AeroVironment Helios, where its inherent lack of stiffness literally twisted itself apart shortly after takeoff.

CONCEPT

Attaining persistent flight requires a paradigm shift in the vehicle design. By taking the best features of both glider and helicopter design methodologies, a new concept vehicle is able to incorporate each of their benefits while minimizing their detriments.

Glider vs Helicopter

Glider Attributes

Gliders demonstrate extreme aerodynamic efficiency, from their long slender wings which reduce drag. But this design approach is limited by structural material properties.

PROS

Aerodynamic vehicles with minimal drag

Utilize long slender wings (high aspect ratio)

CONS

Thin wings lead to bend and twist

Physical constraints limit the aspect ratio

Requires additional material to mitigate bending

Cannot hover or takeoff vertically

Helicopter Attributes

Helicopter rotor blades, which bend under their own weight, are stiffened through centrifugal forces. Unfortunately, rotorcraft are not aerodynamically efficient vehicles.

PROS

Vertical takeoff and landing (VTOL)

Centrifugal forces stiffen thin rotor blades

CONS

Not aerodynamically efficient

Triangular span loading

Complex rotor mechanism

Must withstand extremely large forces

Best of Both Worlds

A new concept vehicle combines the best features of both glider and helicopter design methodologies.

Apply centrifugal stiffening within a glider wing to further increase the aspect ratio and aerodynamic efficiency

Eliminate wasted inboard material from a traditional rotor to achieve better aerodynamics

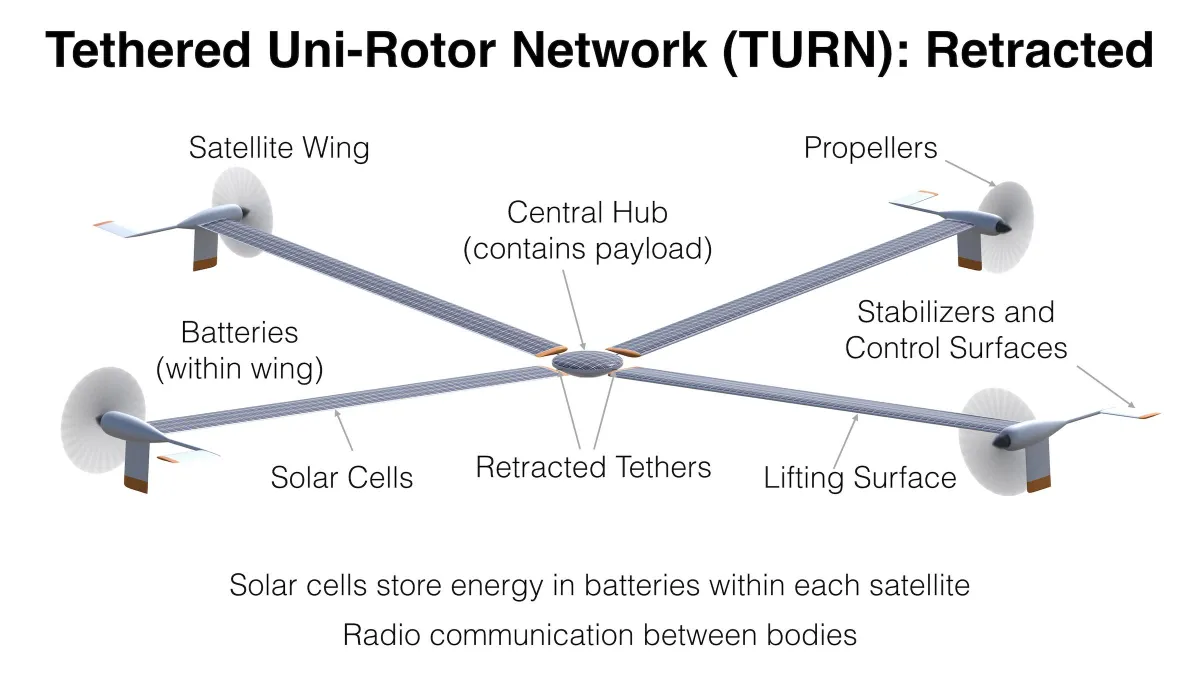

Introducing the Tethered Uni-Rotor Network (TURN)

Without further ado, lets unveil this revolutionary new concept vehicle, named the Tethered Uni-Rotor Network (TURN). The system employs a unique alternative approach, which exceeds existing capabilities, outpaces current research efforts, and will be the answer to attain persistent flight.

Vehicle Layout

The TURN system has a central hub which stores the vehicle payload. Several high tensile, small diameter cable tethers radiate outwards from the central hub. At the end of each tether, a satellite body is attached at the outboard position. Each satellite contains all the components typically found on an aircraft system, including: an airfoil lifting section, small propeller for propulsion, several control surfaces, and a fuselage containing batteries, hardware, and sensors. Each satellite resembles a flying-wing aircraft, which provides all the lift, propulsion and control for the TURN system. The propeller is mounted on the leading edge of the wing, located near the outer wingtip. Immediately behind the prop, stabilizers and control surfaces are located directly in the prop wash. The concept was named Tethered Uni-Rotor Network because a network of aircraft systems are tethered together to form a much larger singular rotor system.

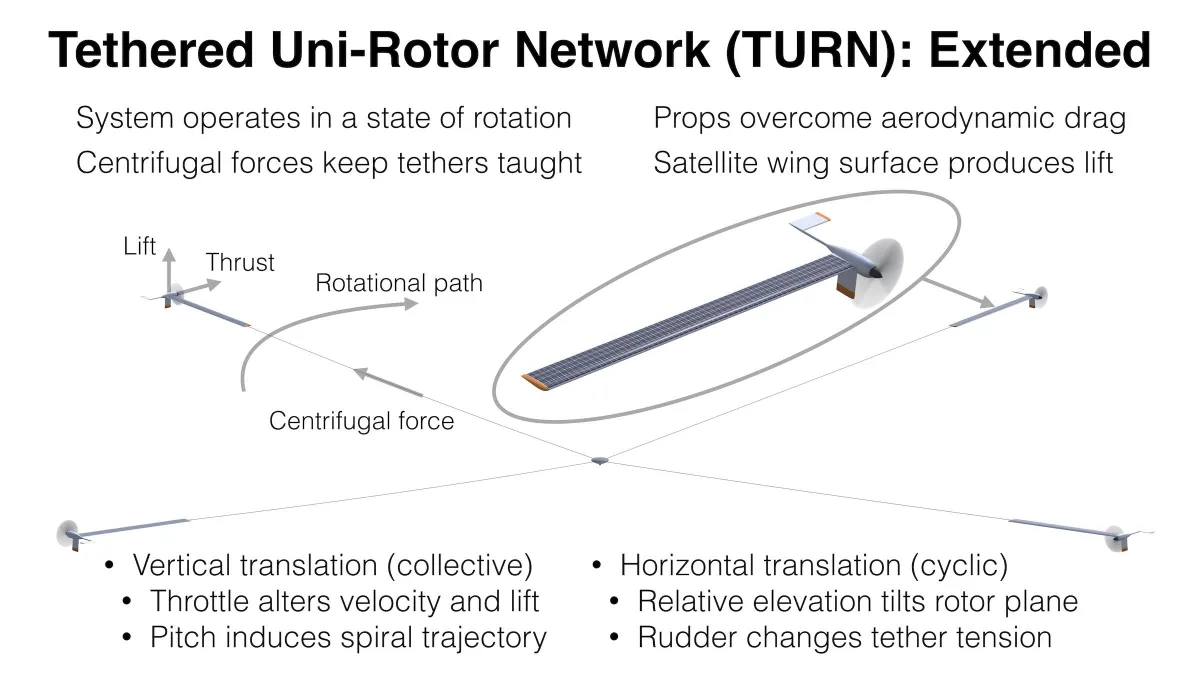

Hover Operation

During flight, the vehicle operates in a perpetual state of rotation. Each of the satellite bodies drive the rotation of the system with their respective propulsion systems, which have an optimum twist and pitch designed for the rotation rate. This propulsion technique is opposite that of a conventional helicopter rotor, where a torque is applied to the central shaft, which requires a counter-torque to prevent the helicopter body from spinning in the reverse direction. Since this is a tip driven system, there is no torque transmitted back to the central hub. Because the system is spinning, centrifugal forces keep the tethers taught and mitigate bending moments commonly present within thin wing sections. As the satellite bodies move through the air, lift is generated on each of the winged airfoil sections, which is enough to counteract the weight of the satellite, and a distributed portion of the weight of the central hub.

Flight Operation

Individual satellites are controlled through their propeller and control surfaces, and the central hub is controlled by coordinating the tether forces imparted from the satellite vehicles. Two types of translation are considered, vertical and horizontal, which have a parallel in helicopter terminology as “collective” and “cyclic” commands. Each type of translation has two associated control modes which can be implemented through different control inputs.

VERTICAL TRANSLATION:

Vertical translation uses “collective” commands where each satellite adjusts its settings in unison. Adjusting throttle increases or decreases the velocity of the satellite, and thus the angular rate of the TURN system. This changes the amount of airflow over the wing, which increases or decreases the total amount of lift generated, and causes the vehicle to ascend or descend. Alternatively, adjusting the pitch of each satellite through the elevator control surface, causes each satellite to nose up or down, thus the entire system will climb or fall as each satellite moves through a spiral trajectory.

HORIZONTAL TRANSLATION:

Horizontal translation is achieved with “cyclic” commands, where the control inputs are changed in a sinusoidal fashion throughout the rotation. The first cyclic command is applied to the vertical control surface, which manipulates the amount of tension on the tether. At one point in the rotation there is maximum pull from the tension, and exactly opposite that point there is a minimum tension force. This imbalance causes the TURN system to translate horizontally. Another approach uses cyclic elevator commands to achieve horizontal translation. At one point in the rotation a satellite passes a low elevation, and at the exact opposite point the satellite traverses a high elevation. This essentially tilts the plane of rotation, which inclines the thrust vector coming from the airfoils, and yields a horizontal force component. This type of thrust vectoring is identical to how traditional multirotors translate horizontally.

SYSTEM BENEFITS

01.High Aspect Ratio

Typical aircraft have AR of 10 where 10-20% of the vehicle mass resides in the wing.

HALE aircraft target AR of 25, but require 40-50% of the vehicle mass in the wing to add stiffening.

Helicopters have AR of 50, while the rotors only account for 2-3% of the total vehicle mass.

02.Wings Placed Under Tension

Mitigates bending moments and flexibility typically found on fixed-wing aircraft.

Reduces the amount of structural material needed to add stiffness within the wing section.

Allows for much larger aspect ratios and greater efficiency without additional material.

03.High Lift-to-Drag Ratio

Centrifugal stiffening allows for very thin airfoils with low thickness-to-chord (t/c) ratios.

Large diameter means the system can cruise at a low airspeed and low Reynolds number.

Rotors are not operating in the downwash field of their neighbor which helps the aerodynamics.

Significantly larger swept area reduces the disk loading across the system.

04.Accommodate Bulky Payload

Bulky payloads on traditional aircraft have drag from the cruise speed required to produce lift.

TURN payload is housed in the stationary central hub, which is independent from lift generation.

Thus, large bulky payloads do not incur the same drag penalty seen with fixed-wing aircraft.

05.Greater Energy Storage and Density

The vast majority of fixed-wing aircraft can only allocate 40% of vehicle for battery mass.

Reduced structural material with TURN, means nearly 80% of the vehicle mass resides in batteries.

Most unmanned aircraft rely on Li-Po batteries because they require the high discharge capacity.

TURN is a low-power concept, so it can utilize Li-Ion or Li-S batteries, which nearly doubles the energy storage for the same battery mass.

06.Slow System Rotation Rate

Helicopters rotors must spin at very high angular rates, because 97% of the vehicle mass is suspended from under the swashplate.

TURN concept has large masses concentrated at each of the wingtips (from batteries).

This substantially reduces the angular rate, where the largest system takes over 30 seconds to complete a single revolution.

Thus, each wing moves more slowly (lower power), and is away from other downwash fields (better aerodynamics).

RESEARCH GRANTS

NASA NIAC (source link)

- Mark Moore (Principal Investigator): Performed feasibility study analysis against a baseline flying wing aircraft, operating at 47 deg latitude on the worst winter day, capable of mitigating winds aloft for 99% of days (~120 mph), supporting a payload that draws 1.3 kW of power; sized vehicles at four different scales.

- Justin M Selfridge (Controls Research Lead): Modeled the dynamics of each rigid body element; developed the numerical multibody simulation model, which captures the nonlinearities within the wing and tether, and couples the forces/moments between elements; devised custom trimming and linearization process.

- Sean Brown (Aerodynamics Lead): Completed aerodynamic modeling within Vehicle Sketch Pad with a constant chord length and optimized twist for the non-uniform free-stream velocity.

- Todd Hodges (Experimental Prototype Lead): Used a Commercial-off-the-Shelf (COTS) control line RC aircraft to collect flight data for a single tether-arm operating in a Round-the-Pole (RTP) configuration.

UNIVERSITY OF VIRGINIA DOCTORAL DISSERTATION (source link)

Justin M Selfridge (Dissertation Author)

- Controls development for the Tethered Uni-Rotor Network (TURN).

- Paradigm shift from global inertial reference frame to relative rotating reference frame.

- Nested adaptive control laws for relative positioning and collective/cyclic control for waypoint navigation.

- Assessed wind robustness and disturbance rejection within simulation models.

- Demonstrated controllability and stabilization within the passive central hub.

US AIR FORCE AFRL PHASE I SBIR (source link)

Justin M Selfridge, PhD (Principal Investigator)

- Solicitation called for a medium-altitude unmanned aerial system (UAS) with 250-lb 2000-W payload.

- Lower operational altitude required a traditional air-breathing combustion engine.

- Revised simulation models to account for mass change resulting from fuel burn.

- Closed designs for 7-day and 30-day endurance drones.

- Secured first Customer Memorandum from US Air Force for aerial wildfire monitoring.

CIT CRCF GRANT (source link)

Justin M Selfridge, PhD (Principal Investigator)

- Developed next prototype demonstrating the manufacturing process for thin-wing structures.

- Replace labor intensive spar/rib structure, with solid foam core and external carbon fiber composite skin.

- Collected flight data within VICON motion capture studio to validate nonlinear dynamics from dissertation.

- Demonstrated and validated control law architectures on physical hardware platform.

- Secured second Customer Memorandum from US Air Force for Agile Combat Employment (ACE).

US AIR FORCE AFWERX PHASE I STTR (source link)

Justin M Selfridge, PhD (Principal Investigator)

- Created Geometric Programming (GP) optimization for optimal sizing across entire flight envelope.

- Devised custom Attitude Heading and Reference System (AHRS) algorithm for state estimation.

- Benchmarked performance against computationally intensive Extended Kalman Filter (EKF).

- Demonstrated coordinating flight maneuvers with multiple tether arms in real-time on hardware.

- Secured Letter of Support from CACI to deploy their Alternative Position/Navigation/Timing payload.

VIDEOS

AUVSI Xponential: Interview with Justin M Selfridge, PhD; Devorto's Founder/CEO.

757 Pitch: The TURN concept wins first place at this pitch competition.

APPLICATIONS

Persistent flight has a wide variety of applications across a number of different industries. But the unique TURN design also allows for an alternative embodiment, including small scale commercial drone and airborne wind energy applications.

High Altitude Platform Station (HAPS) Use Cases

Placing a black-box sensor payload within the stratosphere, provides all the services as our existing and aging satellite networks, but at vastly reduced cost, complexity, and signal latency. Furthermore, HAPS offers capabilities that satellites cannot deliver, like atmospheric monitoring and broadband speed transmission data rates for global Internet connectivity.

Civilian Applications

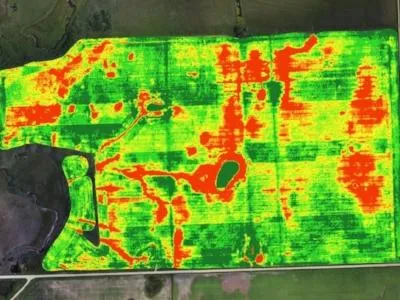

Agricultural Health Monitoring

Crop Disease Tracking

Wireless Broadband Internet

Satellite Phone Connectivity

High Fidelity Imagery

Atmospheric Observations

Extreme Weather Monitoring

Hurricane Prediction

Tornado Monitoring

Pollution and Air Quality Studies

Glacier Ice Dynamics

Volcano Monitoring

Government Applications

Forest Fire Monitoring

Search and Rescue

Border Patrol

Global Mapping

Disaster Assessment

Internal Combustion Engine Embodiment

The TURN concept was awarded Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) grants sponsored by the US Air Force. Research investigated a variation of the TURN system, employing an internal combustion engine. While not a persistent flight solution, the predicted flight endurance vastly exceed what other current unmanned systems can attain.

Mission Requirements

Payload: 250 lb, 2000 W

Medium Altitude: 10k-15k ft

Wind Tolerance: 50 knots

Best Available: 5 day flight

Research Investigation

Fuel burn alters TURN dynamics

Investigated full flight envelope

Revised struct/aero models

Nonlinear optimization

TURN Capabilities

Satisfies mission requirements

Wingspan: 45 feet

Withstands hurricane wind speeds

Exceeds 30 day endurance

Smaller Scale Commercial Drone

The primary benefit of the TURN concept is its extreme aerodynamic efficiency. That feature holds even at smaller scale systems, while still offering hover and vertical takeoff and landing (VTOL), which will yield a formidable competitor within the existing fixed-wing and multirotor commercial drone industry.

Potential Customer

Price sensitive consumer

Hover capability is desirable

Doesn't require eternal flight

Requires longer flight endurance

Existing Fixed-Wing

12 foot wingspan

5 pound payload

Needs a launch site

60-90 min flight endurance

TURN System

Remove solar cells to reduce cost

Same payload capacity

20X more efficient than multirotor

10.0+ hr flight endurance with VTOL

Airborne Wind Energy (AWE) Platform

Existing wind turbines are only applicable for 15% of the Earth's surface, and larger scale systems are not cost effective. New interest has focused on AWE devices which can collect more energy by tapping into stronger and steadier winds at higher elevations. These systems have some shortcomings which can be directly mitigated by a TURN design methodology.

AWE Approach

Eliminate tower structure

Energy kites fly higher

Collect more energy

Greater number of locations

AWE Limitations

Long tether subject to drag

Bending loads on kite wing

Limited trajectory control

Inefficient multirotor for hover

TURN Improvements

Rotates around stationary hub

Eliminates primary tether drag

More aerodynamically efficient

Increased directional control